In today’s globalized wave of customization, there is often a tension between standardized supply chains and increasingly diverse customer demands. At DHPO, we’ve chosen to stand firm—right in the gap between convention and impossibility.

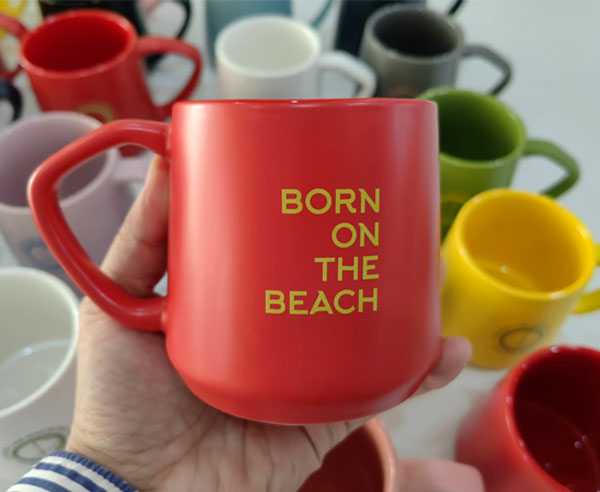

In 2024, a customer from Puerto Rico reached out to us. They run an upscale beachfront club and, after discovering our products online, were immediately drawn to our distinctive design aesthetic. They decided to introduce several DHPO ceramic cups into their retail collection, including:Ceramic Cappuccino Coffee Cup CM230-04A, Ceramic Espresso Coffee Cup CM90-03A, Mini Cappuccino Coffee Cup CM90-02A, Ceramic Capuccino Coffee Cup CM230-04A, Ceramic Mug CM450-02A

A Demanding Customization Request

The project was as exciting as it was complex:

5 product models × 11 colors = 55 unique combinations.

Packaging had to include 40 single-pack boxes and 60 double-pack boxes per color—covering multiple formats and structures.

Beyond Industry Norms: High Complexity, High Barrierst

According to traditional ceramic manufacturing standards, the minimum order quantity for each color is typically 500 units, and custom packaging requires at least 500 per design to justify mold setup, glaze mixing, and decal printing costs. This project didn’t meet any of those thresholds.

We asked if the client would consider simplifying—fewer colors or standardized packaging—but they remained firm. They wanted to offer customers the freedom of color selection and creative combinations. Their insistence prompted us to reflect on our own brand values.

Rising to the Challenge: A Project Rooted in Altruism and Craftsmanship

After numerous internal discussions, we made a bold decision: we would take on the project and do everything possible to help it succeed.

The challenges were significant:

1. 55 variants with unique logo decals in various colors and sizes—a highly intricate production process.

2. Frequent mold and glaze changes due to small batch quantities, increasing risks of cross-contamination and material waste

3. Complex decal preparation, requiring precision at every step

4. Packaging complications with low volumes and multiple box types—necessitating coordination with several packaging suppliers to make it work.

Many Suppliers Would Say No — But We Choose Value Creation

Let’s be honest—most ceramic manufacturers would’ve declined this order outright. The low volume, decentralized production flow, and complicated packaging needs fall far outside the bounds of traditional mass-production logic. But DHPO is different.

Rooted in the philosophies of traditional Chinese values, we believe that real business growth stems from altruism. When we help our customers succeed, we create meaning and value that, in turn, elevate our brand.

Every Commitment Shapes Our Brand’s Soul

RThe successful delivery of this complex project represents more than just our production capabilities—it reflects our unwavering dedication to our brand mission. Going forward, we’ll continue to refine every product with care, staying true to our core belief: empowering customer success.

We firmly believe: when you truly stand in your customer's shoes and go the extra mile, your brand's impact becomes lasting and unforgettable.

Why Do Customers Choose to Cooperate with Us

24 Aug 2025

We are currently developing DHPO distributors and agents worldwide

Join Us